Installing ceramic tile floors and backsplash can transform any space, adding style and durability to your home. Whether you’re working on a kitchen renovation, bathroom upgrade, or simply updating a room, ceramic tiles are a great option for their beauty and long-lasting quality. At Detroit Training Center, our Ceramic Tile Floors and Backsplash Workshop will teach you the essential skills to complete these projects with confidence. With workshops priced at $70 for one person and $120 for two, you can attend at 9:30 AM or 1:30 PM and get hands-on experience in tiling techniques.

This article provides a step-by-step guide to installing ceramic tiles, giving you a taste of what you’ll learn in the workshop, while highlighting the importance of quality products like those available at Lowe’s.

Step 1: Gather Your Materials

Before beginning any tile installation project, it’s important to have all the necessary tools and materials. For a professional-quality finish, you’ll need:

Ceramic tiles (available at Lowe’s, like Style Selections Brighton Ceramic Tile)

Tile adhesive or mortar

Notched trowel (for spreading adhesive)

Tile spacers

Tile cutter or wet saw

Grout (Lowe’s offers TEC Power Grout for durability)

Grout float (for applying grout)

Sponges and buckets (for cleaning)

All of these products can be found at Lowe’s to ensure you have the right materials for a high-quality finish.

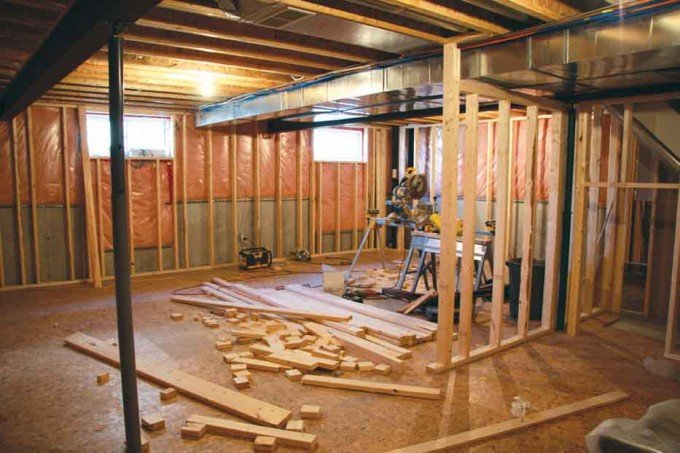

Step 2: Prepare the Surface

Proper surface preparation is key to a successful tile installation. You’ll learn this critical step during our workshop, where our instructors will show you how to assess and prepare your workspace.

For floors, ensure the subfloor is clean, dry, and level. If necessary, use a self-leveling compound to smooth out any uneven areas.

For backsplashes, make sure the wall is free of grease, dirt, or loose paint.

In both cases, applying a primer or backer board may be needed, depending on the condition of your surfaces.

Step 3: Apply Adhesive

Using a notched trowel, spread tile adhesive (also called mortar) onto the surface. Hold the trowel at a 45-degree angle to create grooves that help the tiles adhere better. At the Detroit Training Center, you’ll learn how to properly apply the right amount of adhesive to avoid messes or uneven tiles.

Step 4: Lay the Tiles

Once the adhesive is applied, it’s time to start laying your tiles. Press each tile firmly into the adhesive and place tile spacers between them to maintain consistent spacing. Begin from the center of your surface and work outward to avoid awkward cuts along the edges.

For cutting tiles around edges or obstacles, a tile cutter or wet saw is essential. Lowe’s offers great options like the Kobalt Tile Saw, which is perfect for making precise cuts.

Step 5: Apply Grout

After the adhesive has dried (typically 24 hours), remove the tile spacers and prepare to grout. Using a grout float, spread the grout over the tiles, pressing it into the spaces between. This step ensures the tiles stay securely in place while adding a finished look. You’ll learn proper grout application techniques during the workshop, as well as how to select the best grout for your project.

Once the grout is applied, use a damp sponge to wipe away excess grout from the tile surface, taking care not to disturb the grout lines.

Step 6: Clean and Finish

After the grout has set, perform a final cleaning of the tile surface to remove any haze left behind. A clean, polished look is the result of careful cleaning techniques, which we also cover in our Ceramic Tile Workshop.

Hands-On Experience at Detroit Training Center

At Detroit Training Center’s Ceramic Tile Floors and Backsplash Workshop, you’ll get hands-on experience with these steps, ensuring you have the confidence to complete tiling projects at home. You’ll learn not only how to prepare surfaces, apply adhesive, and grout tiles, but also how to troubleshoot common tiling issues and work with a variety of materials.

Workshops are available for $70 for one person and $120 for two, with sessions starting at 9:30 AM and 1:30 PM. These interactive workshops provide expert guidance in a supportive learning environment.

Shop Lowe’s for Quality Tile Products

To ensure the best results, using high-quality materials is essential. Lowe’s carries everything you need to get started, from ceramic tiles like Style Selections Brighton Ceramic Tile to adhesive, grout, and tools like the Kobalt Tile Saw. With their wide selection, you’ll find everything you need to complete your ceramic tile project with confidence.

Sign up for the Detroit Training Center Ceramic Tile Workshop today, and start transforming your space with beautiful, durable ceramic tiles!

4o